Ready to find a career and not just a job? Echelon Electric is looking to expand our Team!

Working Hours:

Monday - Friday :

8:00AM to 4:30PM

Saturday & Sunday :

By Appointment Only

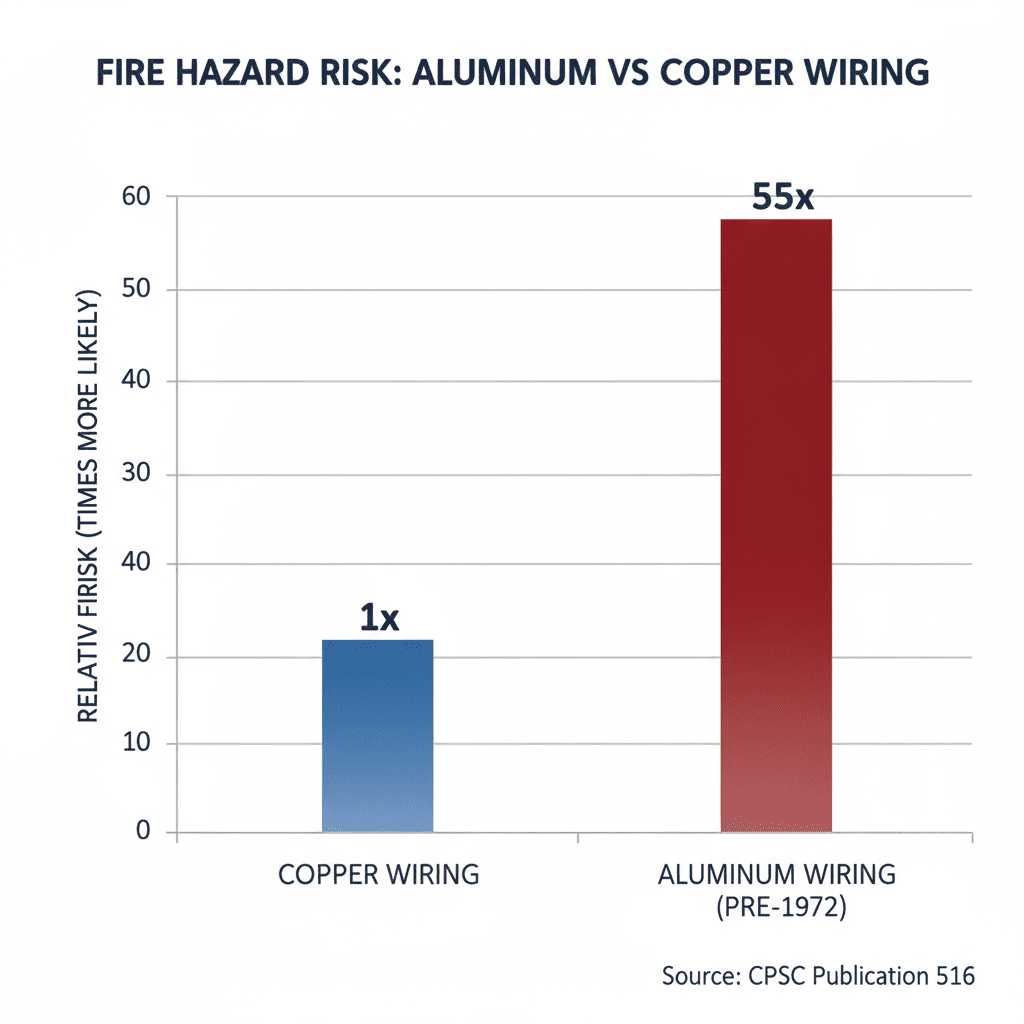

A comprehensive electrical inspection is the first line of defense against hidden electrical hazards. Homes with outdated or improperly maintained electrical systems face a significantly higher risk of fire. For instance, homes with aluminum wiring installed before 1972 are 55 times more likely to have connections reach fire hazard conditions compared to homes with copper wiring[1]. Regular inspections and proactive maintenance by a qualified electrician ensure your home’s electrical system is safe, compliant with current codes, and operating at peak efficiency.

Context: Why This Matters in 2025

In 2025, the demands on residential electrical systems are greater than ever. The increasing adoption of high-draw appliances, electric vehicles, and smart home technology necessitates a robust and reliable electrical infrastructure. Homeowners, insurance providers, and real estate professionals all have a vested interest in ensuring electrical safety and compliance. Authoritative bodies like the National Fire Protection Association (NFPA) and the U.S. Consumer Product Safety Commission (CPSC) continually update standards to address emerging risks. Adhering to these standards, such as the National Electrical Code (NEC), is not just a matter of compliance but a critical step in protecting your family and property from electrical hazards. Proactive maintenance and timely upgrades are essential to meet these evolving demands and mitigate risks associated with aging electrical systems.

Service Coverage & Options

Included Services

- Knob & Tube (K&T) Replacement

- Aluminum Wiring Remediation

- Grounding & Bonding

- 3-Prong & GFCI Conversions

- Electrical Panel Corrections

Typical Use Cases

Our electrical inspection and maintenance services are designed to address a wide range of needs, from routine safety checks to comprehensive system upgrades. We assist homeowners with new installations, replacements of outdated components, and upgrades to meet increased power demands. We also address specific issues like circuit balancing, electrical noise, and ensuring proper airflow for ventilation systems. Whether you are buying a new home, planning a renovation, or simply want to ensure your current system is safe and efficient, a professional inspection is the first step.

| Electrical System Component | Inspection Interval | Key Safety Checks | Code Reference |

|---|---|---|---|

| Main Electrical Panel | Every 3-5 years | Proper labeling, no overheating, correct breaker ratings | NFPA 70B |

| GFCI Outlets | Monthly testing | Test/reset function, proper wiring, ground fault protection | CPSC Guidelines |

| Aluminum Wiring Connections | Annual inspection | Connection integrity, heat damage, proper terminations | CPSC Publication 516 |

| Knob & Tube Wiring | Before any renovation | Active circuits, insulation condition, code compliance | NEC Article 394 |

| Grounding System | Every 5 years | Electrode connections, bonding continuity, resistance testing | NEC Article 250 |

| 3-Prong Outlet Conversions | At installation | Proper grounding, GFCI protection where required | NEC Section 406.4 |

Safety, Codes & Sizing Essentials

Ensuring electrical safety requires adherence to established codes and standards. The National Electrical Code (NEC) provides the benchmark for safe electrical design, installation, and inspection. For example, the NEC requires Ground-Fault Circuit Interrupter (GFCI) protection in all kitchens, bathrooms, garages, and outdoor areas to protect against electrical shock[2]. Proper sizing of circuits and components is also critical. An undersized system can lead to overheating and create a fire hazard. Our inspections include a thorough assessment of your system’s compliance with all applicable codes and standards, as well as an evaluation of its capacity to meet your current and future electrical needs.

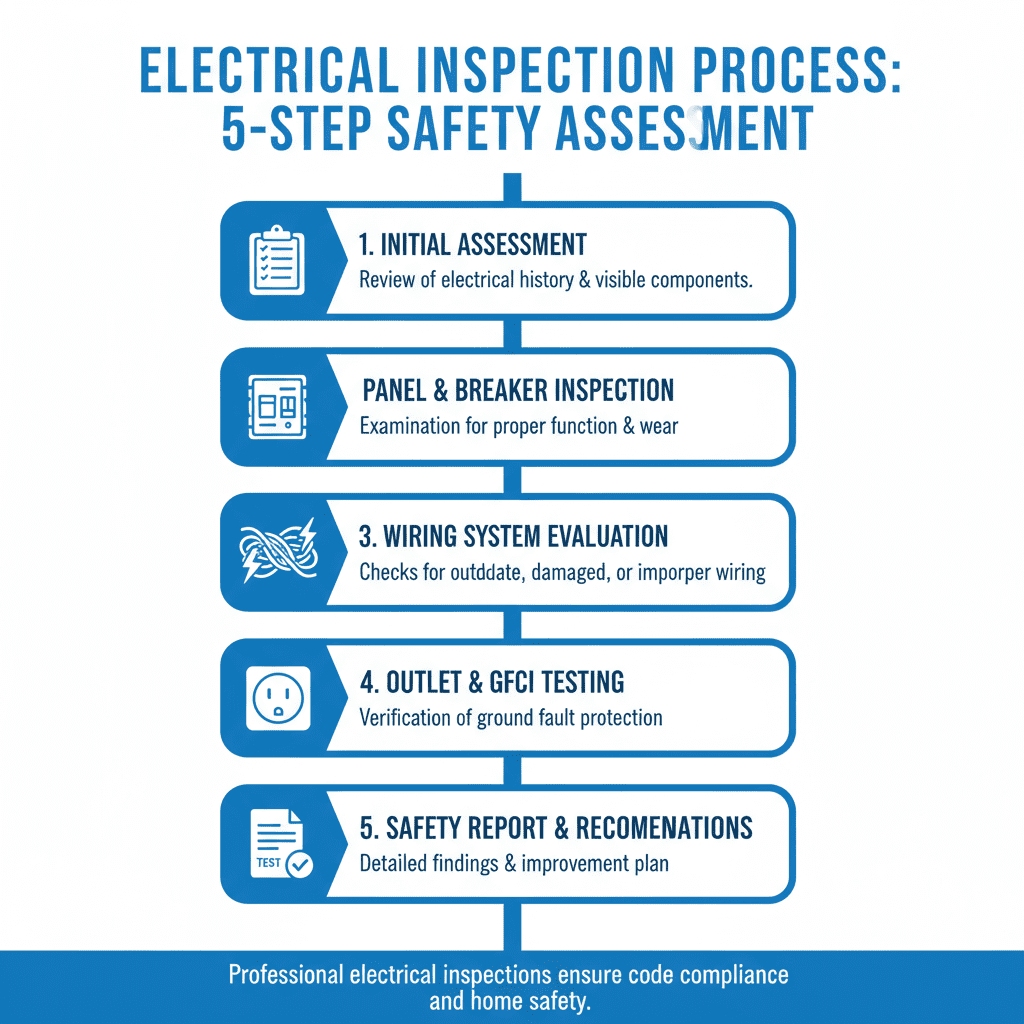

Installation Process, Quality & Limitations

Our electrical inspection and maintenance process is designed to be thorough and systematic. We begin with a comprehensive assessment of your entire electrical system, from the service drop to the individual outlets. This includes a detailed examination of your electrical panel, wiring, and grounding systems. We then provide a detailed report of our findings, along with recommendations for any necessary repairs or upgrades. While we strive to provide the highest quality service, there are limitations to what can be achieved without a full system rewire. For example, in homes with older wiring systems like knob and tube, it may not be possible to add new circuits or fixtures without a comprehensive upgrade. We will always provide a clear and honest assessment of your system’s limitations and recommend the most practical and cost-effective solutions.

Action Plan

Taking proactive steps to ensure your home’s electrical safety is essential. Start by taking note of any persistent electrical issues, such as flickering lights, frequently tripped breakers, or outlets that are warm to the touch. Consider your future electrical needs, such as the addition of a major appliance or an electric vehicle charger. Then, schedule a professional electrical inspection with a qualified and licensed electrician. Echelon Electric serves homes across Howell, Jackson Township, Lakewood, Point Pleasant, Point Pleasant Beach, and Toms River. Contact us today to schedule a comprehensive electrical safety inspection.

Future Outlook

The future of residential electrical systems is focused on greater efficiency, safety, and intelligence. Smart technologies, such as smart panels and integrated control systems, offer homeowners unprecedented control over their energy consumption. Advances in electrical safety, such as arc-fault circuit interrupters (AFCIs), provide enhanced protection against fire hazards. However, these advanced systems also introduce new complexities and potential risks. Improper installation or maintenance can lead to system failures and create new safety hazards. As technology continues to evolve, it is more important than ever to rely on qualified and experienced electricians to ensure your home’s electrical system is safe, reliable, and ready for the future.

Key Takeaways

- Homes with pre-1972 aluminum wiring are 55 times more likely to have fire hazard conditions.

- The NEC requires GFCI protection in all kitchens, bathrooms, garages, and outdoor areas.

- Regular electrical inspections are essential for ensuring safety, code compliance, and system reliability.

- Proactive maintenance and timely upgrades can mitigate risks associated with aging electrical systems.