Ready to find a career and not just a job? Echelon Services is looking to expand our Team!

Working Hours:

Monday - Friday :

8:00AM to 4:30PM

Saturday & Sunday :

By Appointment Only

Professional Electrical Inspections & Code Compliance Services

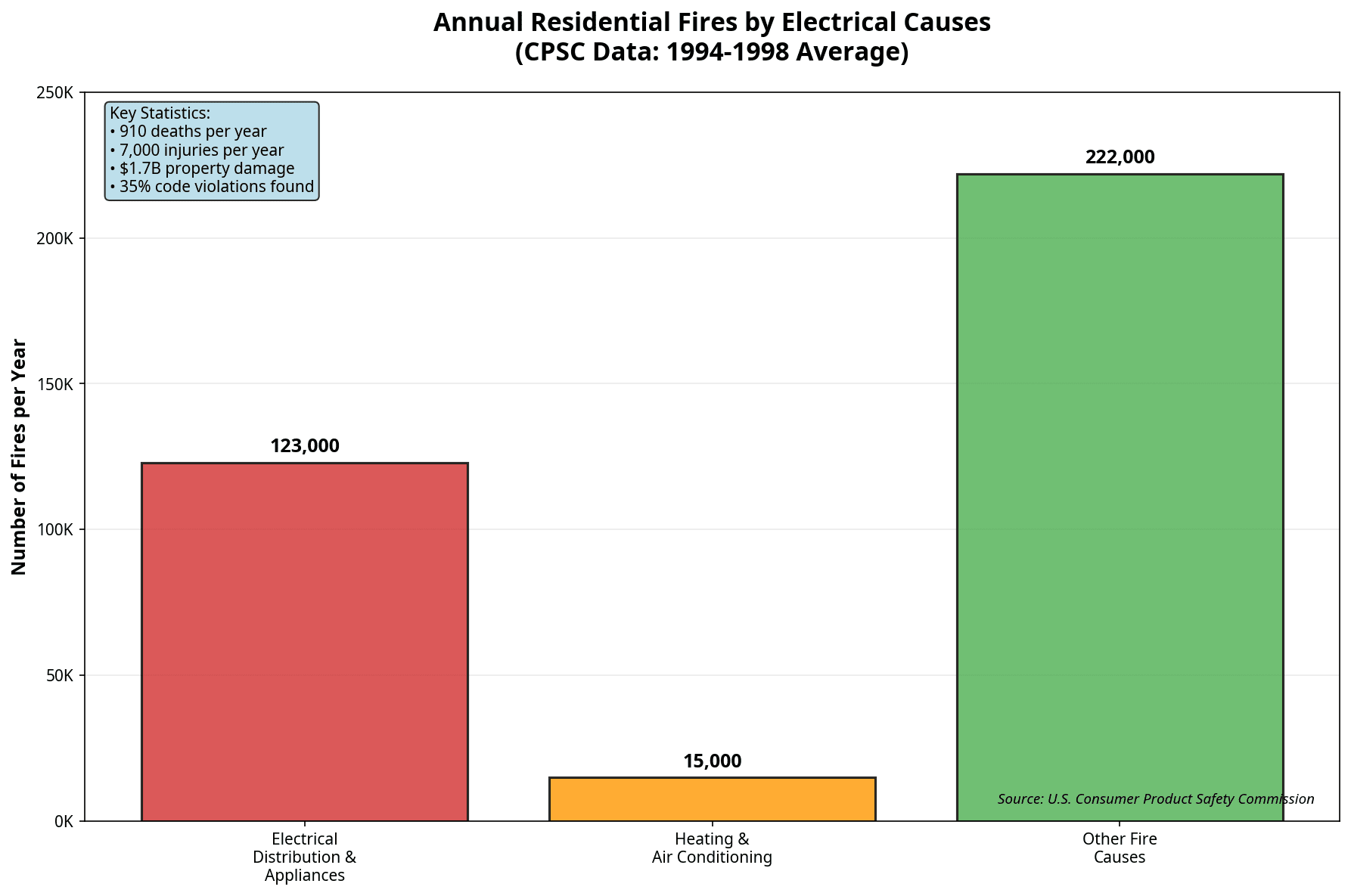

Electrical hazards cause over 123,000 residential fires annually, resulting in 910 deaths and nearly $1.7 billion in property damage each year[1]. Professional electrical inspections identify hidden dangers before they become tragedies, with comprehensive assessments revealing code violations in 35% of residential properties[2]. Echelon Services provides thorough electrical safety evaluations that protect homeowners from fire risks while ensuring full compliance with National Electrical Code standards and local regulations.

Why Electrical Inspections Matter in 2025

The electrical safety landscape has evolved significantly as homes integrate smart technology, electric vehicle charging systems, and high-capacity appliances that strain aging electrical infrastructure. Modern electrical demands frequently exceed the capacity of systems installed decades ago, creating dangerous conditions that standard visual inspections cannot detect. The Consumer Product Safety Commission emphasizes that electrical distribution and appliance-related fires represent the largest category of residential electrical incidents, accounting for over one-third of all electrical fires nationwide[1].

Current building codes reflect these changing demands through updated requirements for Arc Fault Circuit Interrupter (AFCI) protection, enhanced grounding systems, and increased service capacity standards. The National Fire Protection Association’s NFPA 70 National Electrical Code serves as the foundational standard for electrical safety, with new editions released every three years to address emerging technologies and safety concerns[3]. However, many existing homes operate under outdated electrical systems that predate these critical safety improvements.

Homeowners face multiple stakeholders requiring electrical compliance verification. Real estate transactions increasingly demand comprehensive electrical assessments, with buyers and insurance companies requiring documentation of system safety and code adherence. Local jurisdictions enforce electrical codes through permitting processes, while utility companies may require electrical upgrades to support new service connections. Professional electrical inspections provide the authoritative documentation these stakeholders require while identifying potential safety hazards that could result in costly emergency repairs or insurance claims.

The financial implications of electrical non-compliance extend beyond immediate safety concerns. Properties with electrical code violations face reduced market values, insurance coverage limitations, and potential liability issues. Conversely, homes with documented electrical safety compliance command premium prices and qualify for preferred insurance rates. The CPSC recommends electrical inspections for homes over 40 years old, properties with major renovations, and recently purchased residences to ensure ongoing safety and compliance[1].

Service Coverage & Options

Included Services

Our comprehensive electrical inspection services encompass three primary areas designed to address the full spectrum of residential electrical safety and compliance needs. Home safety inspections provide thorough evaluations of existing electrical systems, focusing on fire prevention and occupant protection through systematic assessment of wiring integrity, panel condition, and protective device functionality. These inspections identify aging components, improper installations, and code violations that compromise household safety.

Code corrections services address identified violations through professional remediation that brings electrical systems into full compliance with current National Electrical Code standards and local regulations. Our certified electricians perform necessary upgrades, replacements, and modifications using approved materials and installation methods. This service includes documentation of all corrective work performed, providing homeowners with verification of code compliance for insurance and regulatory purposes.

Real estate inspections support property transactions by providing detailed assessments of electrical system condition, capacity, and compliance status. These evaluations help buyers understand potential electrical upgrade requirements while giving sellers documentation of system condition. Real estate inspections include capacity analysis for modern electrical loads, safety hazard identification, and estimated costs for any recommended improvements.

Typical Use Cases

Electrical inspections serve diverse homeowner needs across various scenarios and property conditions. New installations require verification that electrical work meets current code standards and safety requirements, particularly when adding circuits for major appliances, electric vehicle charging stations, or home additions. Replacement scenarios involve assessment of existing systems to determine appropriate upgrade specifications and ensure compatibility with modern electrical demands.

System upgrades frequently require professional evaluation to determine proper sizing, protection requirements, and installation methods that comply with current codes. Electrical balancing addresses issues with uneven loads, voltage fluctuations, and circuit capacity limitations that affect system performance and safety. Noise and CFM needs assessment helps homeowners understand electrical requirements for ventilation systems, HVAC equipment, and other motor-driven appliances that impact electrical system design.

| Inspection Type | When Required | Key Focus Areas | Typical Duration |

|---|---|---|---|

| Home Safety Inspection | Homes 40+ years old, major renovations | Panel condition, wiring integrity, AFCI/GFCI protection | 2-4 hours |

| Real Estate Inspection | Property sale/purchase transactions | Code compliance, safety hazards, system capacity | 1-2 hours |

| Code Compliance Review | Permit work, renovations, additions | NEC adherence, grounding, overcurrent protection | 1-3 hours |

| Insurance Inspection | Policy renewal, claims assessment | Fire hazards, aluminum wiring, panel condition | 1-2 hours |

Safety, Codes & Sizing Essentials

Electrical safety standards have evolved dramatically over the past decades, with current National Electrical Code requirements reflecting comprehensive understanding of fire prevention and electrical hazard mitigation. The NFPA 70 National Electrical Code establishes minimum safety requirements for electrical installations, with updates every three years incorporating new technologies and safety research[3]. Compliance with these standards significantly reduces fire risk and ensures electrical systems can safely handle modern electrical loads.

Arc Fault Circuit Interrupter (AFCI) protection represents one of the most significant safety advances in residential electrical systems. Current NEC requirements mandate AFCI protection for 15-ampere and 20-ampere branch circuits in bedrooms, living rooms, dining rooms, and other specified areas[4]. These devices detect dangerous electrical arcing that can occur in damaged or deteriorating wiring, providing protection that standard circuit breakers cannot offer. AFCI technology is particularly crucial in homes over 40 years old where wiring insulation may have degraded over time.

Ground Fault Circuit Interrupter (GFCI) protection requirements have expanded beyond bathrooms and kitchens to include garages, basements, outdoor outlets, and other areas where electrical shock hazards exist. The Consumer Product Safety Commission reports that GFCI protection has prevented thousands of electrocutions since its widespread implementation[1]. Modern electrical inspections verify proper GFCI installation and functionality, ensuring these life-saving devices operate correctly when needed.

Category,Annual Fires,Percentage

Electrical Distribution & Appliances,123000,34.2%

Heating & Air Conditioning,15000,4.2%

Other Fire Causes,222000,61.7%

Electrical system sizing requires careful analysis of current and anticipated electrical loads to ensure safe operation and code compliance. Modern homes typically require 200-ampere service capacity to accommodate electric vehicle charging, high-efficiency HVAC systems, and multiple high-wattage appliances operating simultaneously. Undersized electrical systems create fire hazards through overloaded circuits and overheated components, while properly sized systems provide safety margins that accommodate load growth and ensure reliable operation.

Installation Process, Quality & Limitations

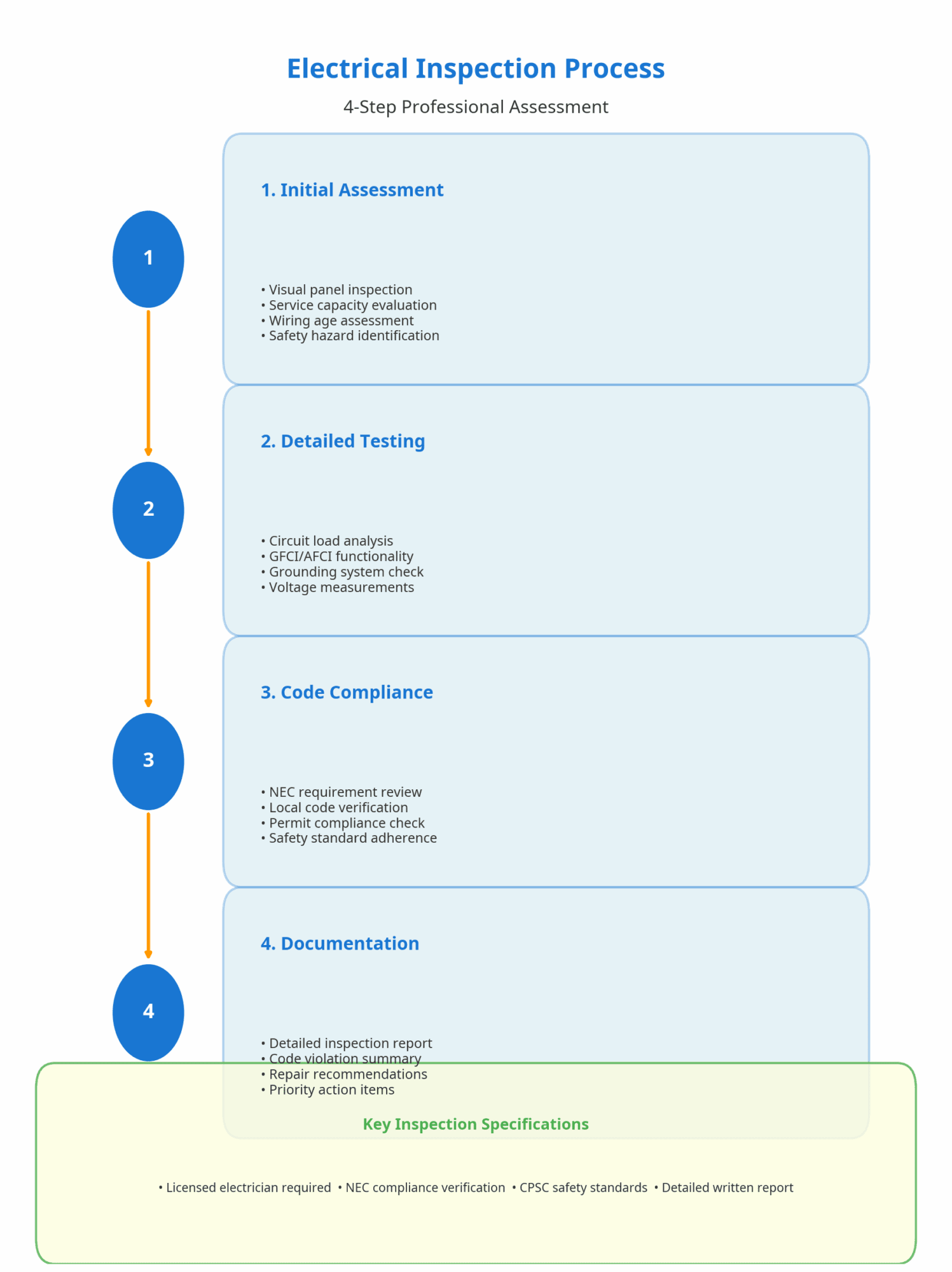

Professional electrical inspections follow systematic methodologies that ensure comprehensive evaluation of all electrical system components and safety features. The initial assessment phase involves visual examination of electrical panels, service equipment, and accessible wiring to identify obvious safety hazards and code violations. Inspectors evaluate service capacity, panel condition, and protective device functionality while documenting system age, manufacturer information, and installation quality indicators.

Detailed testing procedures utilize specialized equipment to measure voltage levels, circuit loads, and protective device operation under controlled conditions. Ground fault circuit interrupters and arc fault circuit interrupters undergo functional testing to verify proper operation, while grounding system integrity receives verification through resistance measurements and continuity testing. Circuit load analysis identifies overloaded conditions and capacity limitations that could compromise safety or system reliability.

Code compliance verification involves systematic comparison of existing installations against current National Electrical Code requirements and local amendments. Inspectors document deviations from code standards, assess safety implications, and prioritize corrective actions based on hazard severity. This process includes evaluation of installation methods, material specifications, and protection requirements that ensure electrical systems meet current safety standards.

Documentation and reporting provide homeowners with comprehensive records of electrical system condition, identified deficiencies, and recommended corrective actions. Professional inspection reports include photographic documentation, priority rankings for identified issues, and estimated costs for recommended improvements. These reports serve as valuable references for insurance companies, real estate transactions, and future electrical work planning.

Quality limitations in electrical inspections stem from accessibility constraints and the inherent limitations of visual assessment methods. Wiring concealed within walls, attics, and crawl spaces may harbor defects that remain undetectable during standard inspections. Intermittent electrical problems may not manifest during inspection periods, requiring extended monitoring or specialized diagnostic procedures to identify. Historical installation practices and grandfathered code provisions can create situations where existing installations meet previous standards but fall short of current safety requirements.

Case study analysis reveals common scenarios where electrical inspections identify critical safety issues requiring immediate attention. A typical example involves homes built in the late 1960s through early 1970s that contain aluminum wiring systems. These installations present fire hazards due to aluminum’s expansion and contraction characteristics that can create loose connections over time. The Consumer Product Safety Commission has identified approximately two million homes with aluminum wiring that require specialized evaluation and potential remediation[1]. Professional inspections identify these installations and recommend appropriate corrective measures.

Additional limitations include the potential for backdrafting in homes with inadequate ventilation systems, undersized electrical service that cannot accommodate modern electrical loads, and moisture intrusion in attic or basement electrical installations. Older wiring systems may lack adequate grounding, while outdated electrical panels may not provide proper overcurrent protection. These conditions require professional assessment to determine appropriate remediation strategies that ensure both safety and code compliance.

Action Plan

Homeowners can take proactive steps to assess their electrical system’s condition and determine inspection needs through systematic evaluation of key indicators and safety factors. Begin by documenting your home’s age, electrical service capacity, and any previous electrical work performed. Homes built before 1980 typically require comprehensive electrical evaluation due to outdated wiring methods and materials that may not meet current safety standards. Properties with 100-ampere or smaller electrical service often need capacity upgrades to accommodate modern electrical loads safely.

Conduct a preliminary safety assessment by examining visible electrical components for signs of deterioration, damage, or improper installation. Check electrical panels for rust, corrosion, or burn marks that indicate potential problems. Test ground fault circuit interrupters monthly using built-in test buttons, and note any outlets that lack GFCI protection in bathrooms, kitchens, garages, and outdoor areas. Document any flickering lights, frequently tripping circuit breakers, or outlets that feel warm to the touch, as these symptoms often indicate underlying electrical problems requiring professional attention.

Evaluate your electrical system’s capacity to handle current and anticipated electrical loads by inventorying major appliances, electric vehicle charging requirements, and planned additions or renovations. Calculate total electrical demand and compare it to your service capacity to identify potential overload conditions. Consider future electrical needs such as electric vehicle charging, solar panel installations, or home additions that may require electrical system upgrades.

Schedule a professional electrical inspection when preliminary assessment reveals potential safety concerns, code violations, or capacity limitations. Choose a licensed electrical contractor with experience in residential inspections and code compliance verification. Request detailed written reports that document all findings, prioritize corrective actions, and provide cost estimates for recommended improvements. Use inspection results to develop a prioritized action plan that addresses safety hazards first, followed by code compliance issues and capacity upgrades.

Professional electrical inspections provide the expertise and documentation necessary to ensure your home’s electrical system operates safely and meets current code requirements. Contact our certified electrical inspection team to schedule a comprehensive evaluation that protects your family and property from electrical hazards. Our detailed inspection reports provide the information you need to make informed decisions about electrical system maintenance and improvements.

Schedule Your Professional Electrical Inspection Today

Future Outlook

The residential electrical landscape continues evolving rapidly as smart home technologies, electric vehicle adoption, and renewable energy integration create new demands on electrical systems. Smart electrical panels with remote monitoring capabilities are becoming standard in new construction, providing real-time data on electrical consumption, circuit loads, and system performance. These advanced panels can detect electrical anomalies, predict maintenance needs, and optimize energy distribution automatically, representing a significant advancement over traditional electrical panels.

Electronically Commutated Motor (ECM) technology is revolutionizing electrical efficiency in HVAC systems, appliances, and ventilation equipment. ECM motors consume significantly less electricity than traditional motors while providing superior performance and reliability. However, these advanced motors require proper electrical supply characteristics and may necessitate electrical system upgrades in older homes to ensure optimal operation and longevity.

Integration of renewable energy systems, energy storage batteries, and electric vehicle charging infrastructure requires sophisticated electrical system design that accommodates bidirectional power flow and complex load management. Modern electrical inspections must evaluate system capacity for these emerging technologies while ensuring proper safety protection and code compliance. The National Electrical Code continues updating requirements for these applications, with new provisions appearing in each three-year revision cycle.

Humidity and indoor air quality integration with electrical systems presents both opportunities and challenges for homeowners. Advanced ventilation systems with humidity sensors and air quality monitors require proper electrical connections and control integration. However, poor ducting design or inadequate electrical capacity can compromise system performance and create safety hazards. Regular electrical inspections help ensure these integrated systems operate safely and efficiently while meeting current code requirements that continue evolving with technology advancement.

Key Takeaways

- Electrical fires cause over 123,000 residential incidents annually, resulting in 910 deaths and $1.7 billion in property damage, making professional inspections critical for home safety[1]

- Code violations appear in 35% of residential electrical inspections, highlighting the widespread need for compliance verification and corrective action[2]

- AFCI protection is required for 15A and 20A branch circuits in bedrooms and living areas per current NEC standards, with particular importance for homes over 40 years old[4]

- Professional electrical inspections should be conducted for homes 40+ years old, properties with major renovations, and recently purchased residences according to CPSC recommendations[1]

References

- U.S. Consumer Product Safety Commission. “CPSC, ESFI Warn Consumers About Electrical Hazards In The Home.” June 18, 2003. https://www.cpsc.gov/Newsroom/News-Releases/2003/CPSC-ESFI-Warn-Consumers-About-Electrical-Hazards-In-The-Home-Inspect-and-Protect-Campaign-Encourages-Homeowners-to-Safeguard-Homes

- International Code Council and National Association of Home Builders. “Common Code Noncompliance Survey Report.” February 2019. https://www.iccsafe.org/wp-content/uploads/2019-Common-Code-Noncompliance-Report.pdf

- National Fire Protection Association. “Understanding NFPA 70, National Electrical Code (NEC).” https://www.nfpa.org/education-and-research/electrical/understanding-nfpa-70-national-electrical-code

- AFCI Safety Organization. “AFCI NEC Considerations.” https://www.afcisafety.org/afci-nec-considerations/